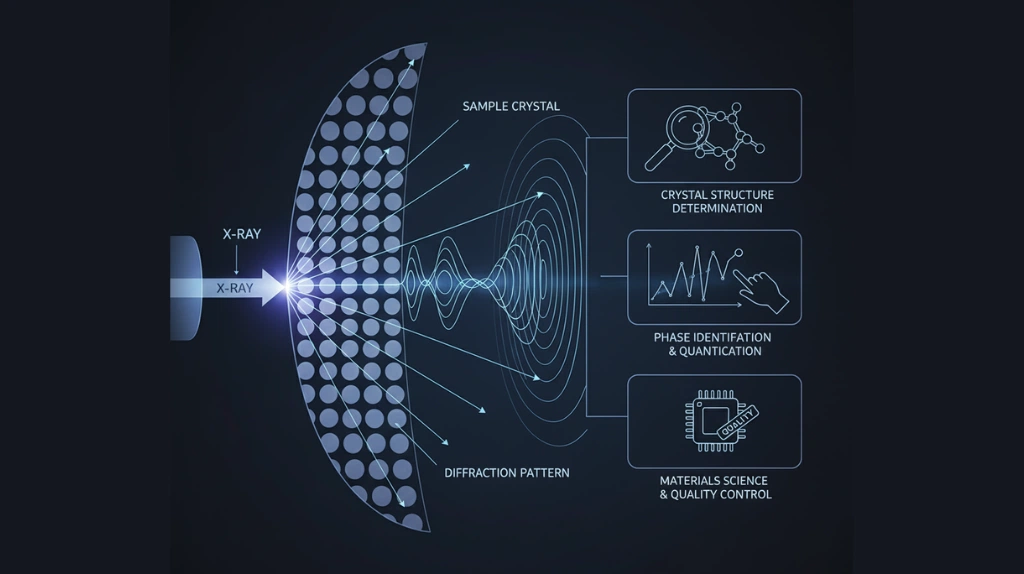

X-ray diffraction (XRD) is a non-destructive analytical technique used to study the qualitative and quantitative properties of crystalline materials, both in powder and solid form.

When a monochromatic X-ray beam strikes a crystalline material, it is reflected—or diffracted—by parallel atomic planes. If the distance between these planes satisfies Bragg’s law, distinct diffraction peaks are generated, which can then be detected and analyzed.

Through XRD analysis, it is possible to identify crystalline phases, measure residual stresses, study crystal texture and orientation, estimate crystallite size and microstrain, and even characterize thin films using low-angle incidence techniques.

X-ray Diffraction: Meaning and Bragg’s Law

At the core of X-ray diffraction (XRD) lies a simple yet powerful concept: every crystalline material is composed of atoms arranged in an ordered, three-dimensional lattice.

When an X-ray beam interacts with this atomic structure, part of the radiation is reflected by the atomic planes.

However, only specific geometrical conditions produce constructive interference, resulting in an intense diffraction signal. This condition is described by Bragg’s Law, formulated in 1913 by physicists William Henry and William Lawrence Bragg, father and son.

In simple terms, Bragg’s Law defines at which angles diffraction occurs and how these depend on the atomic arrangement of the material. Each substance creates a unique “fingerprint” of diffraction peaks — by analyzing their position and intensity, the crystalline composition of the sample can be determined.

This discovery, which earned the Braggs the 1915 Nobel Prize in Physics, is the foundation of modern X-ray diffractometry — a technology that allows us to observe the microscopic world of materials without altering or damaging them.

X-ray Diffractometry (XRD Technology): Instruments and Techniques

X-ray diffractometry makes it possible to practically apply Bragg’s Law to study and characterize the crystal structure of materials.

It is a non-destructive, highly precise, and repeatable technique that provides fundamental information on the internal atomic arrangement of a specimen.

How an X-ray diffractometer works

A diffractometer measures the angles and intensities of X-rays diffracted by a material.

It consists of three main components:

- X-ray source – generates a monochromatic beam, often using copper or cobalt anodes.

- Sample holder – positions the specimen, either stationary or rotating, depending on the measurement.

- Detector – records the diffracted radiation and converts it into digital data, producing a pattern known as a diffractogram.

Each peak in the diffractogram corresponds to a specific atomic plane of the crystal lattice. By analyzing these peaks, it is possible to identify the phases present, assess sample purity, and measure residual stress or crystallite size.

Why XRD is an essential technique

X-ray diffractometry is indispensable in both research and industry because it:

- Identifies materials based on their crystal structure.

- Provides qualitative and quantitative phase analysis.

- Is non-destructive — the sample remains intact.

- Delivers accurate results even on small or complex samples.

Main Applications of XRD Analysis

X-ray diffraction (XRD) is among the most versatile and reliable analytical techniques for studying crystalline materials. It provides crucial structural and mechanical information applicable across multiple sectors — from academic research to metallurgy, advanced materials, and thin film production.

Residual stress measurement

Residual stress analysis is essential to ensure the reliability of mechanical components, steel structures, and materials subjected to welding, heat treatment, or plastic deformation. XRD enables non-destructive measurement of these stresses by comparing lattice spacing variations with those of a stress-free reference.

💡 Example – GNR Instruments: StressX and EDGE diffractometers are used in steel plants, research laboratories, and universities to assess residual stress, phase composition, and structural integrity of metallic components, in full compliance with international standards.

Crystallite texture analysis

Texture analysis reveals the preferred orientation of crystals in polycrystalline materials. XRD allows the study of how atomic planes are distributed in space, influencing mechanical properties such as strength and ductility.

💡 Typical applications: analysis of rolled sheets, deformed materials, and high-performance aerospace alloys.

Crystallite size determination

By analyzing the broadening of diffraction peaks, XRD enables the calculation of the average crystallite size and microstrain — critical data for developing nanostructured materials and industrial quality control.

Structural and phase identification analysis

Each crystalline phase produces a unique diffraction pattern that can be matched against international databases such as PDF-2 or COD.

💡 GNR’s advanced analysis software automatically compares diffractograms for rapid and precise phase identification in chemistry, metallurgy, and materials science laboratories.

Thin film and coating characterization

Using techniques like Grazing Incidence XRD (GIXRD), it is possible to characterize coatings and thin films with nanometric precision. The analysis reveals information on crystal orientation, internal stress, and coating quality.

💡 Example – GNR Explorer: a high-resolution Theta/Theta modular diffractometer configurable for GIXRD, XRR, and grating analysis. Explorer is used both in laboratories and production lines for characterizing thin films, surface layers, and coatings, combining flexibility with high analytical performance.

Retained Austenite Analysis

Retained austenite is a metastable phase that can persist in steels after heat or mechanical treatment, significantly affecting properties such as hardness, fatigue strength, and dimensional stability. XRD is the reference technique for quantifying retained austenite, distinguishing martensitic, ferritic, and austenitic phases with high precision.

💡 Example – GNR AreX Series: the AreX D (benchtop) and AreX L (laboratory) diffractometers provide accurate and standardized measurement of retained austenite according to international norms, used in steelworks and metallurgical labs to verify heat treatment effectiveness.

👉 Discover AreX D

👉 Discover AreX L

X-ray Diffraction with GNR: Advanced Solutions and Instruments

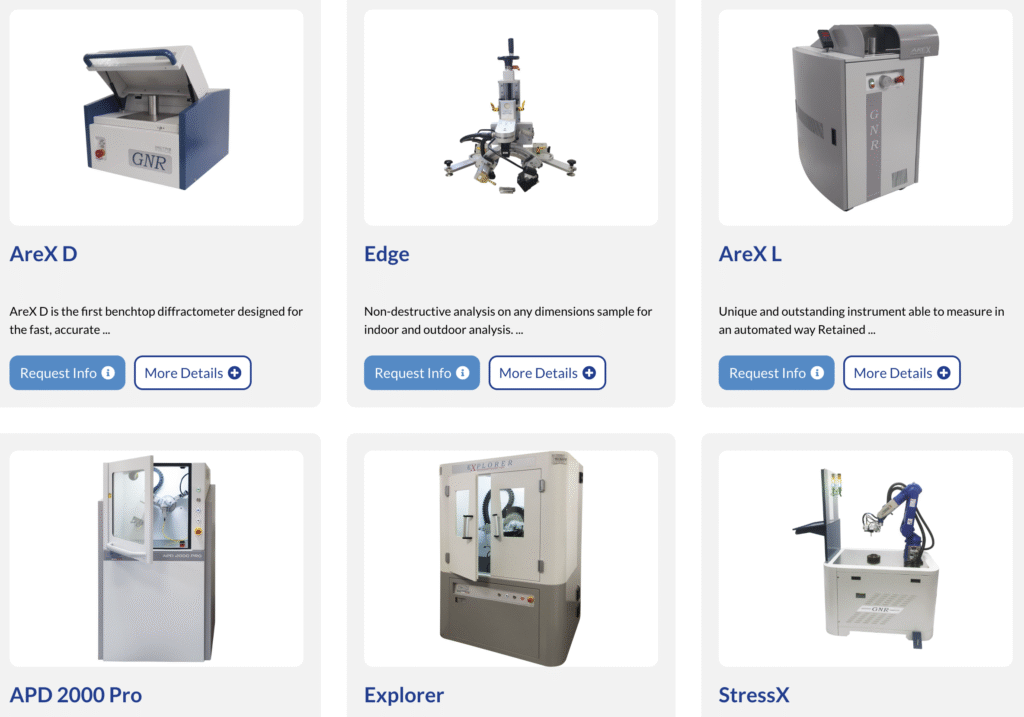

For over 40 years, GNR Analytical Instruments Group has been designing and manufacturing advanced X-ray diffractometers (XRD) for both scientific research and industrial applications.

The company’s long-standing experience in material characterization has led to the development of instruments that combine precision, flexibility, and ease of use, suited for quality control, process monitoring, and advanced material studies.

👉 Explore the full range of GNR XRD Diffractometer

Main GNR XRD Instruments

- AreX D

Compact benchtop diffractometer designed for quantitative analysis of retained austenite in steels and alloys. Ideal for metallurgical and industrial labs requiring fast, reliable, and repeatable results. - AreX L

Laboratory version of the AreX series, equipped with high-stability Theta–Theta geometry and proprietary phase analysis software. Suitable for advanced research and complex samples. - Stress X

Dedicated to non-destructive residual stress analysis, compliant with EN UNI 15305 and ASTM E915 standards. Offers fast, accurate measurements even on large or irregular components. - Explorer

High-resolution Theta/Theta modular diffractometer configurable for GIXRD, XRR, and thin-film applications. Perfect for coatings, surface analysis, and industrial line integration. - EDGE

The most advanced diffractometer in the GNR portfolio, designed for scientific research and complex material characterization. With synchrotron-level performance, EDGE provides top precision for phase, stress, crystallinity, and multilayer structure analysis.

Thanks to continuous R&D collaboration with academic and industrial partners, GNR ranks among the leading European manufacturers of XRD instrumentation, offering customizable, automated, and software-integrated solutions.

Innovations and Future Trends in X-ray Diffractometry

XRD technology is undergoing a period of rapid evolution, driven by the demand for compact, automated, and intelligent instruments. New generations of diffractometers now combine high analytical precision with shorter measurement times, meeting the needs of both research and industrial laboratories.

According to Archive Market Research (2025), “Advancements in XRD technology are leading to more efficient and precise analysis, expanding its adoption across advanced materials, pharmaceutical, and nanotechnology industries.”

Meanwhile, Global Growth Insights (2025) reports that the global XRD market—estimated at $0.746B in 2024—is expected to exceed $1B by 2033, driven by miniaturization, automation, and AI-powered software solutions.

Recent research published on arXiv (2025) introduces the Lab-3DμXRD method (Laboratory-based 3D micro-beam XRD), enabling three-dimensional, non-destructive material characterization directly in laboratory environments.

These advances, combined with robotics and AI-driven workflows, are shaping the next generation of diffractometry — faster, smarter, and more accessible than ever before.

FAQ

XRD is used to study the crystalline structure of materials, identifying phases, measuring residual stress, determining crystallite size, and analyzing thin films or coatings — all without damaging the sample.

2. What physical principle underlies XRD?

It is based on Bragg’s Law, which states that diffraction occurs when X-rays interact with atomic planes at specific angles that satisfy the wavelength–distance relationship.

3. What are the main applications of XRD?

Metallurgy, materials science, pharmaceuticals, electronics, nanotechnology, and environmental studies — anywhere crystal structure and composition are critical.

4. What XRD instruments does GNR offer?

GNR designs a full range of diffractometers, including AreX D, AreX L, StressX-2, Explorer, and EDGE, covering everything from industrial quality control to advanced scientific research.

5. What are the future trends in XRD?

Miniaturization, automation, and AI integration. GNR continues to develop modular, automated, and intelligent XRD systems designed to meet the evolving needs of research and industry.